July 2017 - August 2017

About The Company |

My Project |

|

AKELA Inc. is a company in Goleta, California that designs and builds radars for various clients. These radars serve a variety of purposes and are often used by the US Department of Defense. For more information, visit their website:

www.akelainc.com |

I worked on a radar cart project during my internship. The cart has to transport equipment and have a large arm so the radar can go in front of the cart to detect objects in front of the operator. For this project, I worked with engineers at AKELA to incorporate design specifications and constraints to create a CAD model for the cart. I then worked on manufacturing components for the base and steering system.

|

Skills Gained: SolidWorks, Design, Teamwork, Research, Manufacturing

DESIGN

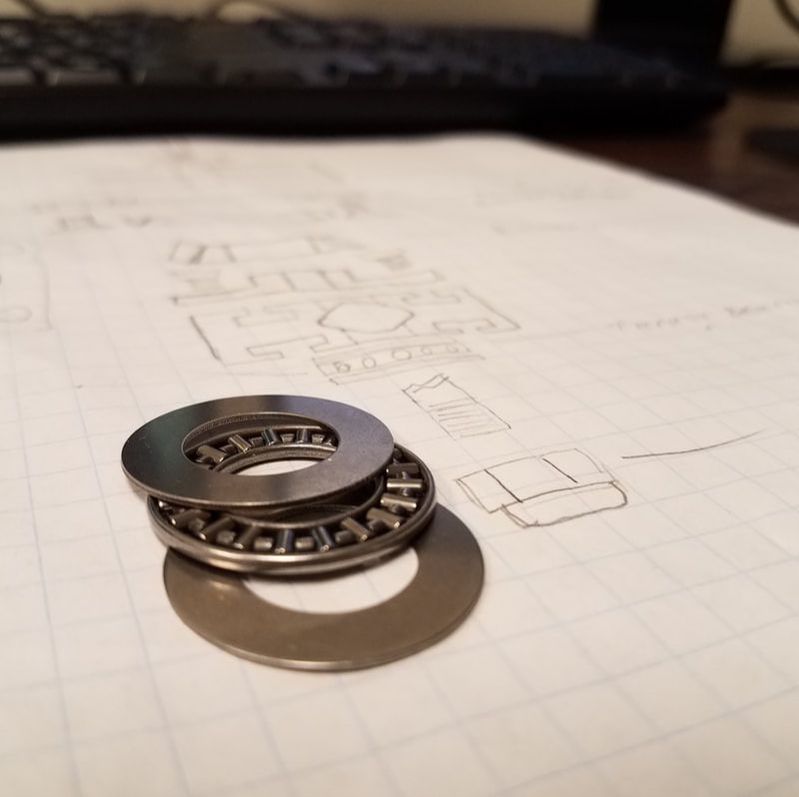

ResearchI began the project by gathering data about the requirements, design constraints, and ideas they had. I then researched aspects of the cart such as steering systems, implementing bearings, and materials. From that data, I was able to begin designing.

|

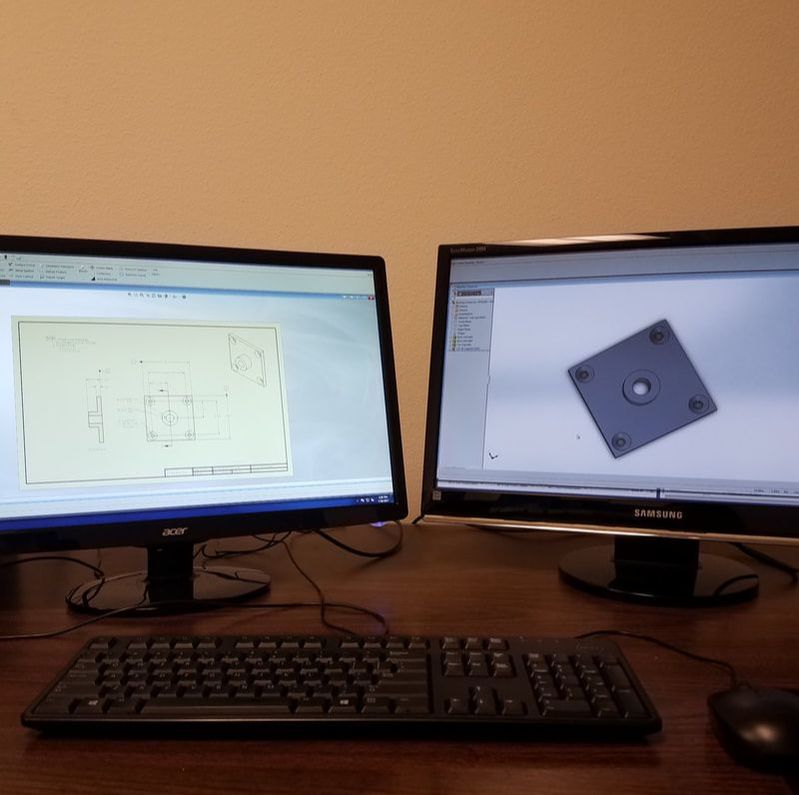

ModelI used SolidWorks to create a model for each potential design. I used these models to create manufacturing drawings for each part I made. After each major component was designed, I presented it to my supervisor for feedback and to discuss any design changes. While creating the manufacturing drawings, I performed calculations about the thermal expansion to determine the necessary tolerances.

|

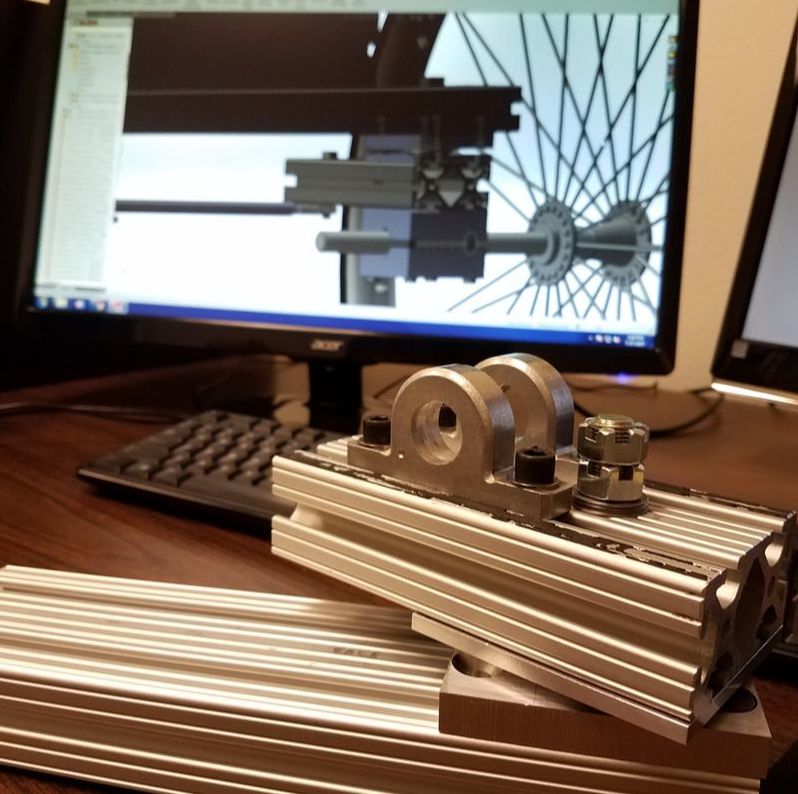

PrototypeBefore manufacturing all the parts for the cart, I worked with my supervisor to create a prototype for the steering system design. This helped us test out some ideas and adjust out design as necessary. After we had a working prototype, I began manufacturing.

|

MANUFACTURING

After designing the radar cart, I created manufacturing drawings for the necessary parts. I then used a manual mill, CNC mill, and drill press to manufacture them. This experience helped me learn how to design for manufacturability, complete projects given a time constraint, and manufacture parts that meet design requirements.