April 2018 - Present

|

About Cal Poly Shop Technicians:

Mechanical Engineering machine shops at Cal Poly are open to students of all majors who have completed a safety training course and test. Shop Technicians train students, demonstrate how to use machines, and oversee the daily use of the machine shops. |

Skills: Manufacturing, Critical Thinking, Communication, Patience

Experience: Manual Mill, Manual Lathe, CNC Mill, Laser Cutter, Plasma Cutter, Mig Welder, Tig Welder

|

Machine Shop Projects

Projects are explained further below.

Manual Lathe:

|

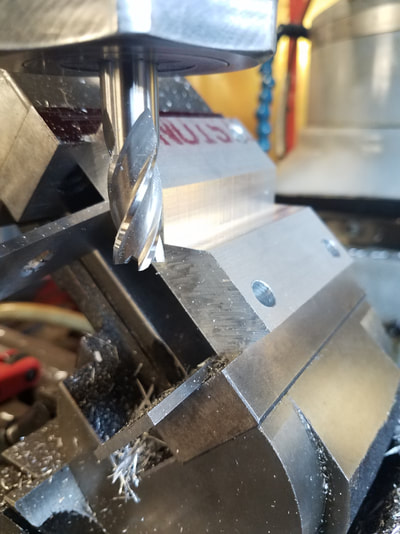

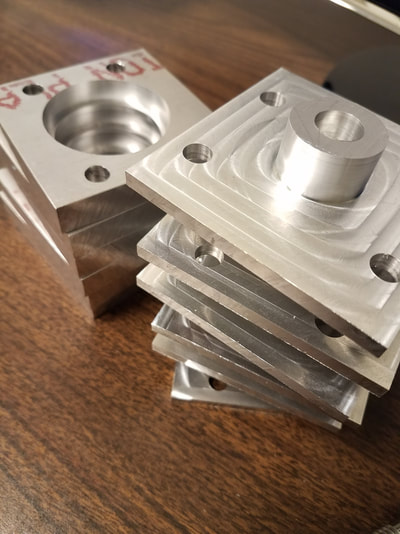

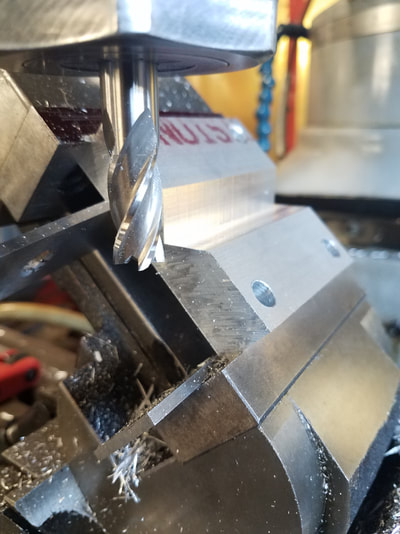

CNC Mill:

|

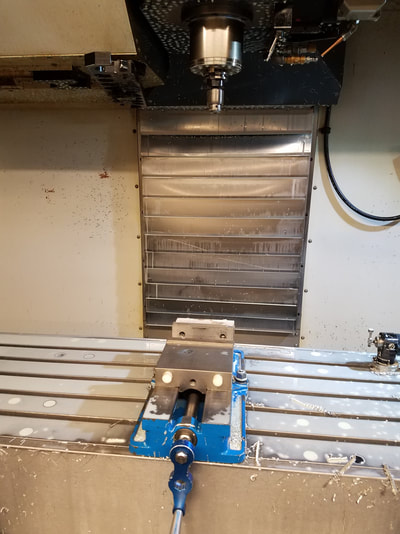

Manual Mill:

|

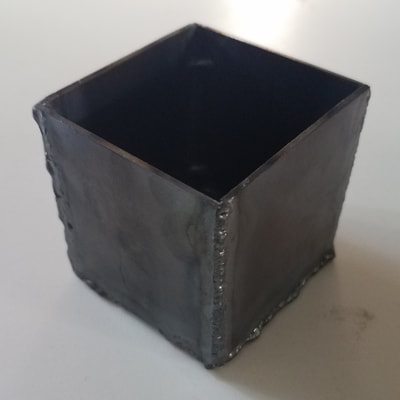

Tig Welding:

|